What is Precision CNC Machining of Stainless Steel Turned Parts?

Precision CNC machining of stainless steel turned parts refers to the use of computer numerical control (CNC) technology to manufacture turned components from stainless steel. CNC machines use highly automated processes to create parts that meet exact specifications, offering superior precision and repeatability compared to traditional manual machining methods.

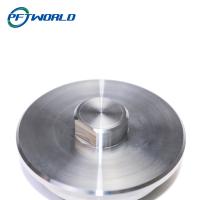

The term "turned parts" refers to components that are shaped using a lathe, where a rotating workpiece is cut using tools to create cylindrical or spherical shapes. Stainless steel is commonly used for turned parts due to its high strength, resistance to corrosion, and aesthetic appeal. When combined with CNC machining, stainless steel turned parts can achieve tight tolerances and superior finishes, making them ideal for demanding applications across various industries.

Key Benefits of Precision CNC Machining of Stainless Steel Turned Parts

1.Unrivaled Precision and Accuracy One of the primary benefits of precision CNC machining of stainless steel turned parts is the exceptional accuracy it offers. CNC machines are capable of making highly precise adjustments, ensuring that every component is manufactured with tight tolerances and the required dimensional accuracy. This precision is crucial for industries that require parts to fit seamlessly into larger assemblies or systems without errors.

2.Superior Material Properties Stainless steel is chosen for its excellent mechanical properties, including resistance to corrosion, high tensile strength, and durability. Precision CNC machining enhances these characteristics, allowing manufacturers to produce turned parts that maintain their integrity even under harsh conditions, such as extreme temperatures, chemical exposure, or high-stress environments. This makes stainless steel turned parts ideal for industries like aerospace, automotive, and medical.

3.Enhanced Surface Finish The high-precision nature of CNC machining allows manufacturers to achieve an excellent surface finish on stainless steel turned parts. A smooth, polished surface not only improves the part’s aesthetic quality but also enhances its functionality. For example, smoother surfaces reduce friction, extend the lifespan of components, and are easier to clean and maintain, which is especially important in the medical and food processing industries.

4.Consistency and Repeatability CNC machining ensures that every part is produced with the same level of precision, which is critical for high-volume production runs. Whether you are producing one part or thousands, precision CNC machining of stainless steel turned parts guarantees uniformity in size, shape, and finish. This consistency reduces the risk of defects and minimizes the need for rework, improving overall efficiency and reducing costs.

5.Complex Designs and Customization Precision CNC machining of stainless steel turned parts is ideal for producing complex, intricate designs with tight tolerances that would be difficult or impossible to achieve with manual machining. From small components with detailed features to larger, more complex parts, CNC machining allows for customization to meet the exact needs of a particular application. Additionally, factory customization options allow you to tailor dimensions, materials, and surface finishes for specific projects.

Common Applications for Precision CNC Machining of Stainless Steel Turned Parts

- Aerospace: Precision components such as fasteners, brackets, and structural parts that must meet exacting standards for safety and performance.

- Automotive: Parts like shafts, gears, and suspension components that require durability, strength, and the ability to withstand extreme conditions.

- Medical: Surgical tools, implants, and devices that require precise dimensions and a smooth finish to ensure functionality and patient safety.

- Food and Beverage Processing: Components such as valves, pumps, and nozzles that must resist corrosion and contamination while meeting strict hygiene standards.

- Electronics: Housings, connectors, and other components that require strength, precision, and a sleek, smooth finish.

The Advantage of Factory Customization for CNC Machined Stainless Steel Parts

Factory customization of precision CNC machining of stainless steel turned parts is key to meeting specific requirements across various applications. Customization options include:

- Material Selection: Different grades of stainless steel (such as 304, 316, or 17-4 PH) can be selected to suit specific needs based on factors like corrosion resistance, strength, or weldability.

- Design and Geometry: CNC machining allows for intricate geometries, fine details, and custom features that are essential for unique part designs.

- Surface Treatments: Factory customization can also involve various surface treatments, including polishing, passivation, anodizing, or coating, to enhance the part's appearance and functionality.

Conclusion

Precision CNC machining of stainless steel turned parts offers manufacturers the ability to produce high-quality, durable components that meet the most demanding standards for accuracy, strength, and performance. Whether you are producing small, intricate parts or large, complex components, CNC machining provides unmatched precision, efficiency, and repeatability. With customization options available to meet the specific needs of various industries, precision CNC machining ensures that your stainless steel turned parts deliver exceptional performance and reliability.

| | CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding,3D Printing,Rapid Prototype,Moulds etc. |

| | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper |

| Titanium: Grade F1-F5 |

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. |

| | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| | ±0.002 ~ ±0.005mm |

| | Min Ra 0.1~3.2 |

| CERTIFICATE | ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE etc. |

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.